Current location: Home > index Pro Foot

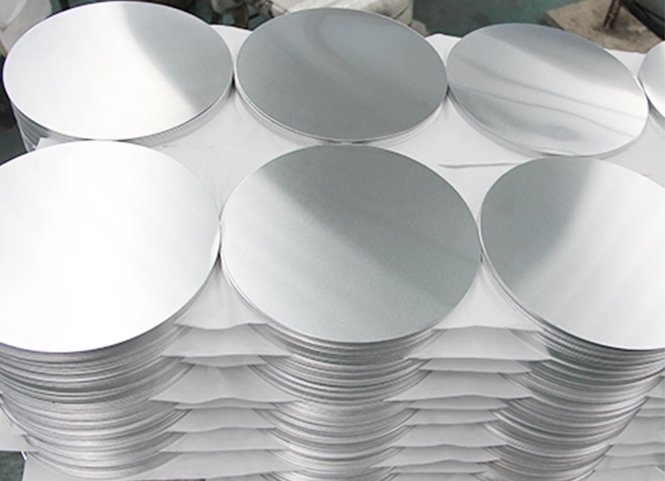

Aluminum Circles are very common in our life. Such as: bottom of a non-stick pan, electrical equipment,heat preservation sealing of a can, traffic sign, lamp and lantern etc. Besides this, aluminum circle is also widely used in machine manufacturing, automotive industry, aeronautics and astronautics, molds,printing,etc.

We can produce both DC and CC material for the aluminum circle, so we have to choose DC or CC according to the application. And normally, the CC material is used in mold, and DC material is suitable the product which need the higher elongation.

1. Low relative density.

Aluminum density is about 2.7g/cm3.

Its relative density is only one-third that of iron or copper.

2. High plasticity.

Aluminum has good ductility, and can be made into a variety of appliances according to the working pressure processing methods such as squeezing and stretching.

3.Corrosion resistance.

Aluminum is a strongly negatively charged metal material. Under natural conditions or anodic oxidation treatment, the surface layer will be converted into a defensive air oxide film, which has much better corrosion resistance than steel.

4.Easy to strengthen.

The compressive strength of pure aluminum is not high, but it can be enhanced by anodizing treatment.

5.Easy surface treatment.

Surface treatment can further improve or modify the exterior characteristics of aluminum.

Aluminum oxidation process is very perfect, the actual operation is stable, has been widely used in the whole process of metal aluminum processing.

6.Good electrical conductivity, easy to recycle.

1. Stock pots,Fry pans,Tea kettles, Electric Skillets, Pressure cookers,Pizza pans,Rice cookers,Non-stick Cookware, Coffee Pots, Fat Fryers,Cake pans, Covers;

2. Stainless Cookware Bottom Plates,Restaurant Cookware,Bakeware,Woks,Bread Makers,Drip Pans,shell of water heater;

3. Hardware item (lampshade):Recessed lighting,High bay industrial lighting,Stress lighting , Lighting lamp , traffic light reflectors,Traffic signs.

|

Typital alloy |

Temper |

Thickness(mm) |

Diameter(mm) |

Type |

|

1050,1060,1070, 1100,3003,3005, 3105,5005,5052, 5083,8011,etc. |

O,H12,H14, H22,H24,H32, H18,etc. |

0.25-6.0 |

CUSTOMIZED |

CC/DC |