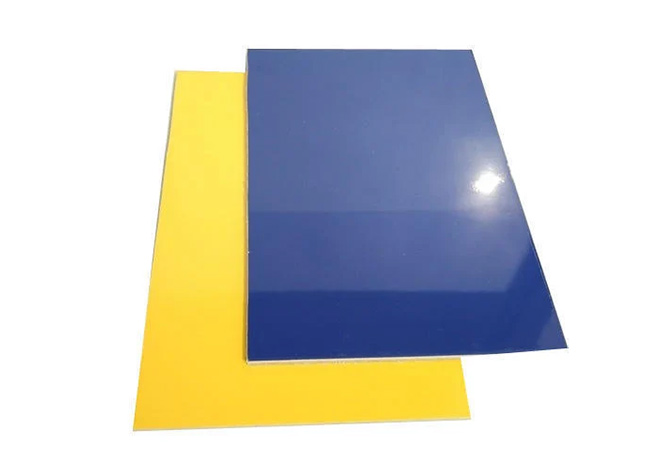

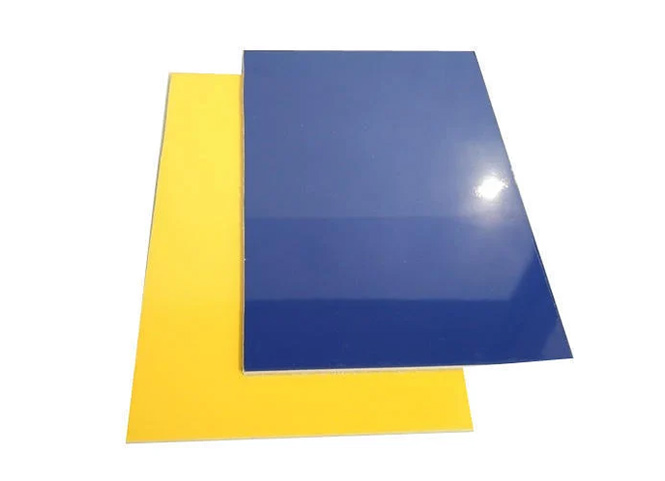

Powder coated aluminum sheet is made of high-quality aluminum alloy material after de-esterification, cleaning and passivation layer processing. On this basis, rollers coating with various colors of fluorocarbon PVDF, to make the aluminum plate durable; this is the great difference color coating aluminum sheets from aluminized and galvanized powder coated aluminum sheet in quality. The product has excellent weather resistance, with stoving varnish from high temperature. It has the advantages of high gloss retention, good color stability and small color difference change. The warranty of PE painting is about 15 years, and for PVDF it's about 30 years.

1.The first suspended ceiling was gypsum board, and it was early in Western countries. At the back, it was an aluminum-plastic panel, and it was a metal-aluminum ceiling not long afterward until now. After centuries of changes and sublimation, powder coated aluminum sheet is mostly used in the market. It is durable, not easily deformed, and has an elegant appearance, so it replaces gypsum board.

2.Powder coated aluminum sheets are also often used as roofing aluminum sheet. The use of aluminum sheet can be easily transported, the surface coating will not be damaged, and the use of equipment to press and transport to the roof at the construction site can greatly improve the construction efficiency.

3.Powder coated aluminum sheet It has the advantages of both aluminum plate and organic material. It not only has the advantages of high mechanical strength, good toughness, and easy processing and forming of aluminum plate, but also has good coloring, decorative, and decorative properties of organic polymer coating materials. Corrosion resistance, it can be easily processed by punching, bending, deep drawing, welding, etc. The products made by aluminium are practical, decorative, easy to process and durable. The adhesion between the printed layer and the bottom layer is high. Powder coated aluminum sheet both can fulfill the demands of different fields, and has a variety of colors. Which provide beauty for our decorative life, So it has been widely used.

4.With the development of science and technology, the enhancement of environmental protection awareness and the improvement of people’s living standards, color coated rolls show its vitality and broad market prospects.

One of its main advantages is that the color-coated aluminum sheet not only has the high mechanical strength of aluminum alloy material, but also has the performance of easy forming, and also has the good decoration and corrosion resistance of coated fluorocarbon material.

Widely used for interior decoration, ceiling plate, wallboard, roof, furniture, all kinds of exterior wall and interior.

|

Typital alloy |

Color |

Thickness(mm) |

Width(mm) |

Coating thickness |

Coating material |

|

1050,1060,1100, 3003,3005,5052,5754etc |

RAL, pantone, our color chart or sample color request. |

0.2-5.0 |

Customized |

8-25μm or request |

PVDF / PE |